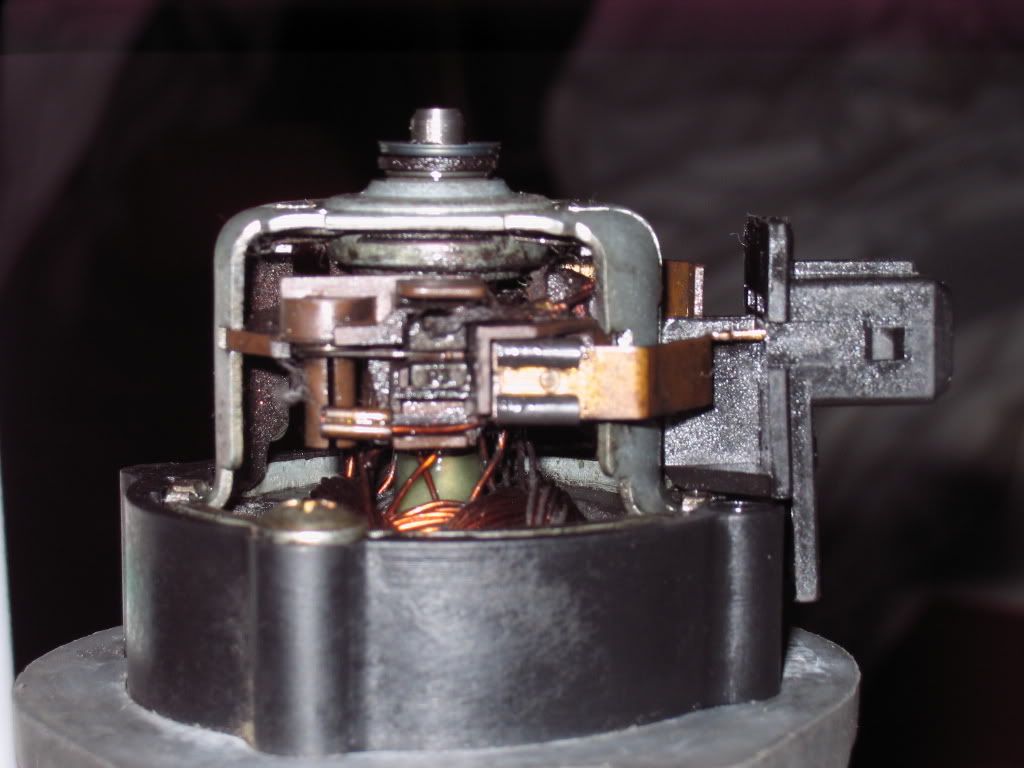

Just under the bracket that supports the bearing you will find the felt oiler pad, impregnate with oil, and a few drops at the top where the shaft goes through the bearing.

At the fan end I decided not to try to remove the fan, so got a piece of earth sleeving and slid it down to the shaft, and proceeded to drip oil through the sleeve, which worked quite well. Got about 30 drops in, with none running out, so it should have found its way to the felts.

You have to be patient but the fan was noticeabley free`er, and the slight movement in the bearing went. Before reassembling the fan, I switched on my overide for the fans, and plugged the motor in, and it ran OK. So then I reassembled the unit and put it back in the Alp (dont forget the other felt washer that goes around the rear bearing before you put the end cap on) ran the fan again, and noticed it was much quieter than before. The whole job took me about 2hrs at OAP pace, but I would recommend it as a job worthwhile doing