1. Casting painting:-

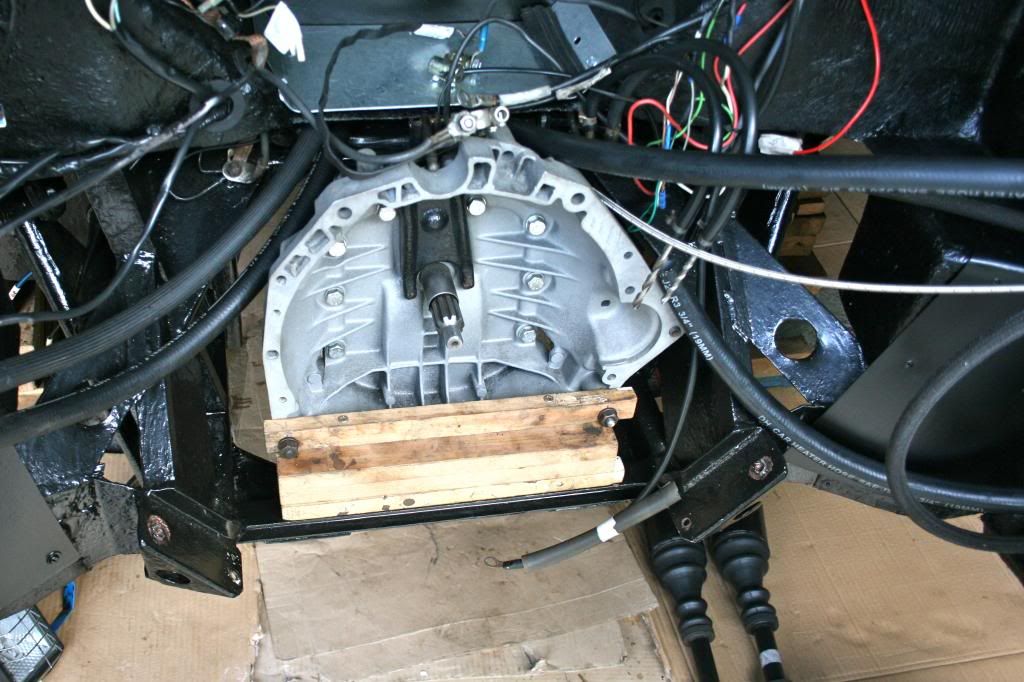

Gearbox - I had the box overhauled by a gearbox specialist and he had the casings vapour blasted once stripped, as far as I know. He suggested that I protect the exterior from oxidation so I gave the whole box a coating with clear lacquer. It's been on for over a year now and still looks good. Bear in mind that the car is not yet mobile and has been garaged.

Rocker and timing chain covers - I had these powder coated.

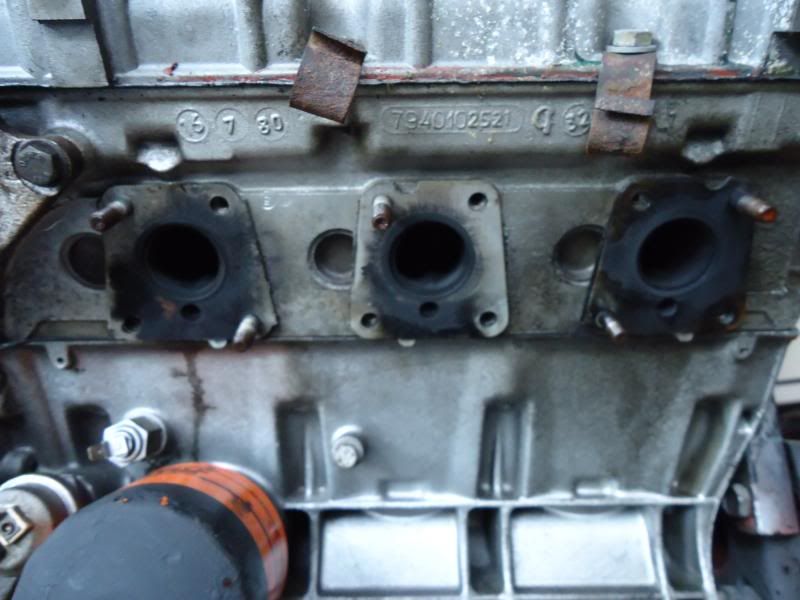

Engine block and lower block - I cleaned off all the oxidation with various sizes of rotary wire brushes in an electric drill. I then washed them and once dry applied a first coat of etch primer, then a coat of aluminium paint followed by a final coat of clear lacquer. As the engine hasn't been run yet I've no way of knowing whether the finish will stand up to temperature, etc.

Sump - The casting was in good condition without any oxydation. So I just cleaned it and gave it a coat of clear lacquer.

2. The fuel pump is as it was when I bought the car and the plating is quite good. It probably looks more shiny in the photo due to the camera flash.

3. I had all the coolant pipes copied by a stainless steel exhaust fabricator due to the corrosion of the original pipes. See this link.

http://www.renaultalpineownersclub.com/ ... lant+pipes

General questions:-

1. Running clearances - I did check the clearances purely to know what they were rather than it being an unknown. I fitted new main and big end bearings and used Plastigauge to check the clearances. This is one of the big end bearings.

I have three reference books which give slightly different clearance values but these below should be representative. Note that my engine has the odd-fire crank with standard main bearings (2.7576" - 2.7583") and standard crank pins (2.0578" - 2.0585").

Main bearing clearance - 0.0014" - 0.0034".

Big end bearing clearance - 0.0011" - 0.0031"

Crankshaft end float - 0.0027" - 0.0106"

2. Rebuild gotchas - I'm an amateur, but have built a few engines over the years.

- Take plenty of notes as you dismantle, measure and record.

- Take plenty of photos.

- Get hold of an engine manual which will tell you all the things to look out for. I bought a couple of manuals from an autojumbler at a classic car show some time ago for £2.00. They are:-

- Haynes Volvo 260 series 1975 - 1985 workshop manual (ISBN 1 85010 206 6).

- Autobooks Volvo 260 series 1975 - 1978 workshop manual (ISBN 0 85147 719 4).

I'd recommend both, especially the Haynes manual. You might find them on Ebay.

3. I don't have any experience of dbilas cams. Some of the other guys might have.