When I started working on the Renix 1 D501 ecu it was sometime ago, I couldn’t find much information, well non-existent, and so I slowly started reverse engineering it from an electronics and firmware point of view. I’m not going to go head long over the details, but to give you a simple example I didn’t know which chip the calibration details were stored, as I was hoping and assuming it was external to the EF6801U4PV MPU. Noting the OE chip numbers have been replaced by the S Solitary digital integrated circuits designations, so near impossible to work out what they are; this applies to all the Renix / Fenix ecus. However, with a bit of work, buzzing out the address and data bus off the MPU to all the chips it was possible to identify the only chip directly connected to the full databus and the page address space, and hence likely candidate for the storage device containing the map tables for the engine calibration. I had some clues, as I knew what the address mode of the MPU had been set by examining the electroinic hardware initialisation bits of the MPU. Hence, I had pin configuration with some potential candidates, so I then desoldered the device and rigged up suitable hardware to attempt a read, and made a guess as to the likely candidate. This was a success, and 512 bytes the full contents of the PROM (and it’s a N82S147F, and they are no longer manufactured, cannot be erased ie a perm fused device, and NOS are running around £25 landed each) were downloaded, and I now had the task of working out what it was all about. Initially the ecu’s I modified and Lee has provided to folk through RATS had PROMs, and then I went over to doing a chip converter to a 27128A EPROM that allowed me to easily erase and re-write at the rolling road than throw the chip away. For those interested then I do EPROM emulation to work on a soft version of the file, and then burn to a chip when happy.

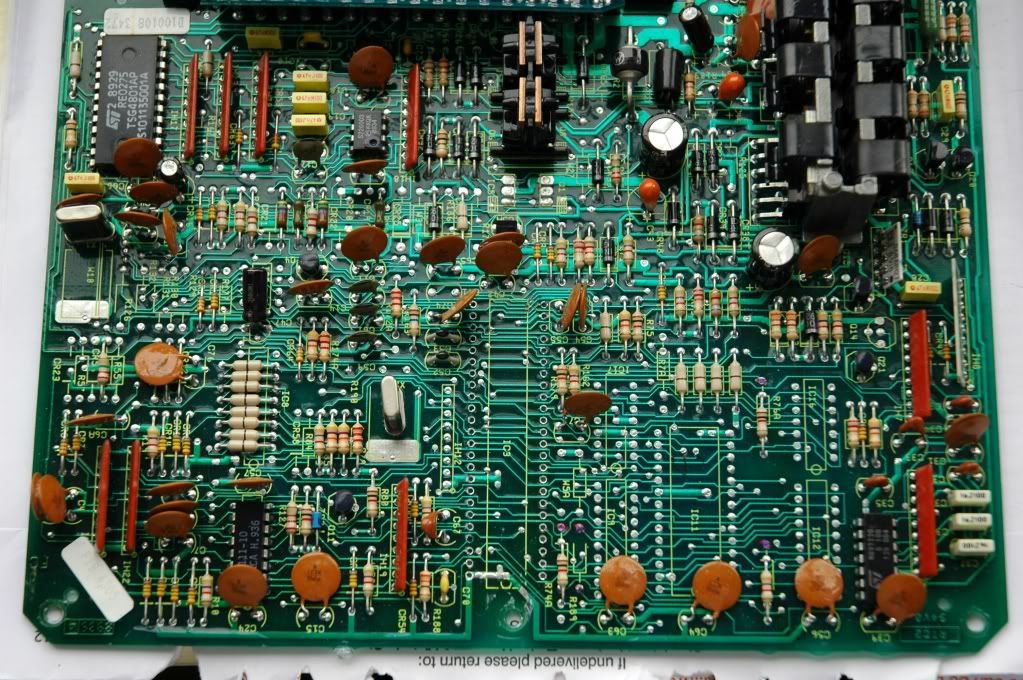

Here’s a modified board to take the eprom, no claims to being pretty, but it does the job. It really needs a little PCB, may be something for JohnC? There are some other mods on the board, but the real crux of the matter is in the Eprom.

The MPU itself contains the firmware (the ecu computer software routine in effect) in the internal ROM, and I have been able to extract it a byte at a time in test mode. However, being unable to modify it is really academic than of real engine tuning interest. I have a number of web links that are useful from an electronics point of view, and

http://www.fenixecu.com/injection-fenix is a good over view of the system for those interested.

On this point of the MPU, they all carry the S designation S100723008A, except one, and this was a S1007233008B in a BBR (Broodie Britain Racing) ecu, and I have this chip. It also has the internal ROM masked so that I can’t hack it and pull the contents out to compare. But this is the only one I have ever seen, and believe me I always check when I see an ecu. I haven’t run it for a long while, and I wonder if it has something to do wth the rpm limit, I should really test it… I am working on another solution to move the 6200 rpm brick wall, and this was inspired by a conversation over messages with Jon Thorn and something he had found… so his will be the first trial and see how we get on.. thanks for that Jon. Anyway, the aim is to move the limit from 6200 to around 6800 rpm, and I hope it works out!

The R25 turbo ecu, same pcb with some differences in component poulation and values carries another firmware version, and is designated S100723003.

I did write a post a few years ago when I started this path, and this brought me in contact with Tommy in Belgium, and he had further parts to the Jigsaw, and found he had much of the information I was after, and could have told me what the PROM chip identification was from the outset if I had been in touch earlier. So many thanks to Tommy, as he has been a massive help, thank you. His interest is mainly the later ecu’s and Fenix 3b especially, but some of the pointers from the later ecus helped me with the earlier ones. There are some very interesting things to note, with one example being as soon as I knew the table for the battery voltage correction in the later generation, I was able to identify it in the very first ecu the Renix 1. Hence, this was established from the very early dyno testing at Bendix, and then copied to every ecu setup from then on… including the R21 turbos, Clio’s etc etc… worth thinking about that.. So the PRV and the GTA has provided some real foundations.

But this brings me back to my favourite topic and moan, there has to be a great deal of information available out there, if only it were accessible… and there must be a few people with the contacts.. but do they have the interest to find out, and would they share? This is now extremely old technology, and I don’t see it being such an issue to be open and allow all to extract the most they can, when aftermarket is such a viable option these days… There is much I don’t know of the Renix 1, and I can’t justify the time to find all the tables, and I’ll put some examples below, but may be.. someone out there does, it would be great if they could share.

My next strategy was to find as many of the GTA D501 ecu’s that I could and see if the calibration values had changed over the production years, and indeed they did. I know of and have the following OE production data calibration settings: earliest first 111B, 111F, 112F, 211D, 311, 501, 601, and 611 (there were little tweaks between them). You can check which one you have by looking for the number on the little white sticker on top of the PROM chip.

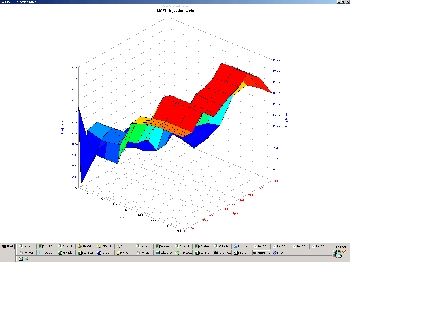

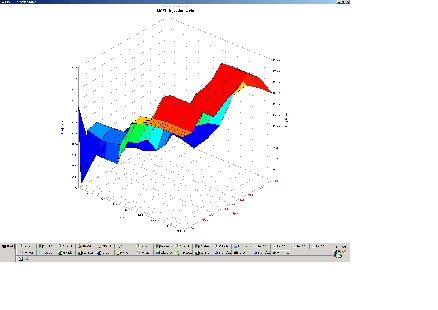

So here is an example of the OE calibration files for fuel:

211D

and here’s BBR’s modified fuelling map… for version 1, surprise surprise they are the same

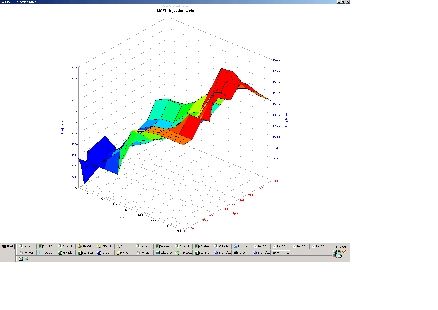

Here’s the last GTA calibration revision I know in production on fuel, and indeed a NOS ECU bought from the factory will now come with this calibration. You should be able to spot the difference to the above:

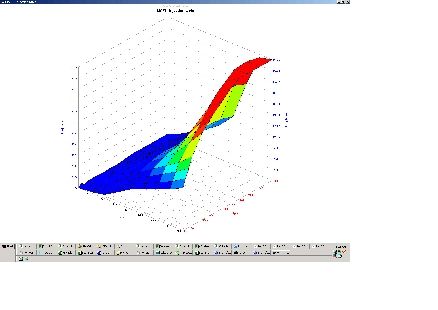

And here’s Teglen’s as tuned by the author for his 280hp upgrade…

Now for technical, and details I’m still looking for…

Renix 1:

Address I know:

002h - version number

004h - calibration revision number Renault

005h - ignition timing base map 9 rows, 13 columns

rpm break points: (I would like to be able to change these)

6000

5250

4500

4000

3500

3000

2500

2250

1800

1200

1000

800

650

MAP break points (psi): (I would like to be able to change these)

-13 -10 -6 -3 0 4 7.1 10.59 14

0eFh - water temp correction on fuelling 9 x 1

125h - battery voltage correction 9 x 1 - this is copied up to the later versions of the ecu and Fenix 3, values have not changed.

Some differences I have not been able to verify what they do, such as location 1FFh - early version it's 64, then 65 in cal 501, then 68 in cal 601. I have not seen any identifiable effect with change, may be some one out there does?

In early calibration version for D501 ecu locations 1E0 and 1E1 were values 0D, 3E and all later version DC, E9 - again does anyone know what this is and why?

14E to 151h - D501 all calibrations have values : 5C 5C, 5C, 5C, and R25 turbo: 52, 52, 52, 52

and

156 to 157h - D501 all calibrations: 8A, 8A and R25 turbo: 70, 70

Interestingly the following block is always the same sequence and same address, any software:

160 to 163h - 14, 0C, 05, 00 - do you know someone that knows what this is?

1e6, 1e7 - I thought this might be another pair for injection restart after injection cut after rev limit, but I am not sure? Do you know anything on these bytes?

Ok, you may say, well that’s a lot of stuff he doesn’t know, and in the most part it doesn’t affect road tuning or fast road motors, but when you want to tweak for track and racing applications there are things you want to control, for example tip in etc. On the Fenixecu site the table definition files shared for the later Renix / Fenix ecus are only the fuel and ignition maps, not giving any further information, and this will do for fast road. However, I also modify the warm-up ramps, knock sensing values etc, and I have had to derive these, and in some cases the hard way… So I’m not about to be giving those away unless asked directly with good reason.

So here’s an example for track use that the limitations of the Renix 1 have eventually driven me to upgrade to the later Renix ecu’s with throttle pots and better control algorithms - I find that the compensation algorithms in the Renix 1 are very basic, mainly limited by the fact it only knows the throttle is either closed, somewhere mid throttle, or fully open. Hence, doesn’t have a real representation of engine air mass flow demands, and this causes issue the higher the boost pressure is raised. So say I am driving, and I have 15psi, I can change the throttle position, obviously change the airflow, the turbo maintains the same MAP pressure, but the Renix can't compensate as the temp has not changed, so it delivers the same fuelling. Consequently I can make the AFR / fuelling vary drastically at the same point, just by the use of the throttle. If I set the fuelling for WOT, and then throttle back slightly I start getting a rich mixture. So here’s the test - I can't see / think of a way round this on the Renix 1.... if you can help, or have any ideas that would be great!

Hence, I’m moving on to the later ecu for Will’s car… a very special ecu – words from Tommy – “The board in the picture is rare. Not very long used. By my knowledge it is only used in the Alpine 2.5 GTA turbo with catalytic converter. From 1988 till 1992. The first ones were with eprom the later ones (89/90->92) were without eprom..” (for those with a sharp eye, I have removed the MPU (big processor chip) from the board to socket it for future playing.

Anyway, I’ll show you how to modify it to external EPROM, as the OE had the code wrapped up in the upgraded MC68HC11 MPU (S101194003) and read / write protected (Benix had got smart to the hackers…). Thanks to the Bi-turbo project I have the necessary before and after electronics modification information as the Bi-turbo ecu was modified, I have an OE unmodified board

, and Tommy has helped me out with BINs. Hence, I can make up a "bad" Renix S101100108A ecu (Tommy had S101100106B, but that may have been for one with the EPROM from the factory?), with an external EPROM and by-pass the internal masked ROM… this has lots of lovelies including soft changeable rpm limits, expanded tables and much more.

More to come in the next instalment… and I would be really grateful for any insights from others engaged with these ecu's.

Thanks,

Martin