Thread copied from Renault Turbo site. This is several posts linked together with some editing to make it make sense where others have contributed.

Car seems very solid with just one rear turret needing a small amount of welding, although they haven't got to the other area of worry to check for corrosion in the box section where the steering rack lives.

Most of the glass is ok which is a relief as is very hard and expensive to source now.

All suspension etc all removed front and rear.

Most of the stripping is now done mechanically and any making good will be done over the next couple of weeks as the parts are assembled for the new V8 subframe.

So plan is to build up a new rear transaxle with new and spare parts I have, that bolts straight in as per original so that the car can be swapped back to original if required. Spare subframe back from shot blasters.

Ordered the engine and ECU yesterday. The lower spec one was on a 6week delivery but they had the next one up in stock so bit the bullet and bought that. Only problem is I'll definitely have to uprate the gearbox now :0(.

This one is being spec of the one being delivered tomorrow.

The Hot Cam Adds Heat to the LS3

Our engineers never stop tinkering. When they took a production LS3 6.2L (376 cubic inches) engine and swapped the stock camshaft for the racing-inspired LS Hot Cam (P/N 88958753), the result was a stunning 495 horsepower and 473 lb-ft of torque. We wasted no time in adding that terrific combination – dubbed LS376/480 – to our crate engine portfolio. The key to the power boost is the Hot Cam’s 0.525-inch lift on both the intake and exhaust sides, along with 219-degree/228-degree duration specs. That’s less lift on the intake side than the stock LS3 cam, but considerably more duration, allowing the valves to stay open a little longer to draw in more air from the rectangular-port L92-style heads.

Use the LS376/480 with a controller kit (P/N 1925267), which includes a special pedal for use with the engine’s electronically controlled throttle.

This weeks update.

Prep work mainly. Rear turrets were pretty good just needed 1 small hole patching.

Front bulkhead, another notorious rust spot, nothing serious just a bit crusty

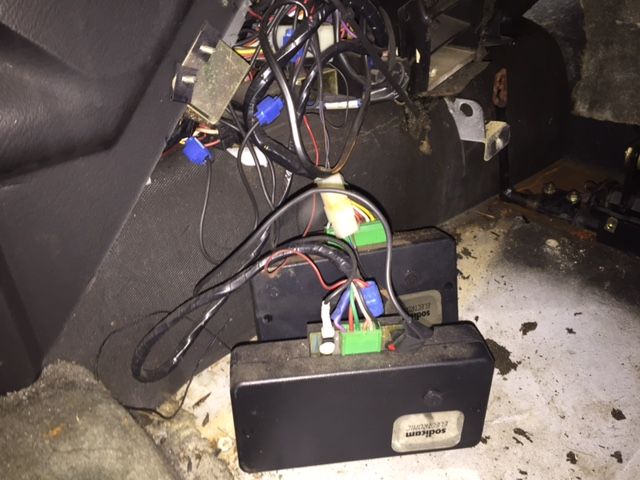

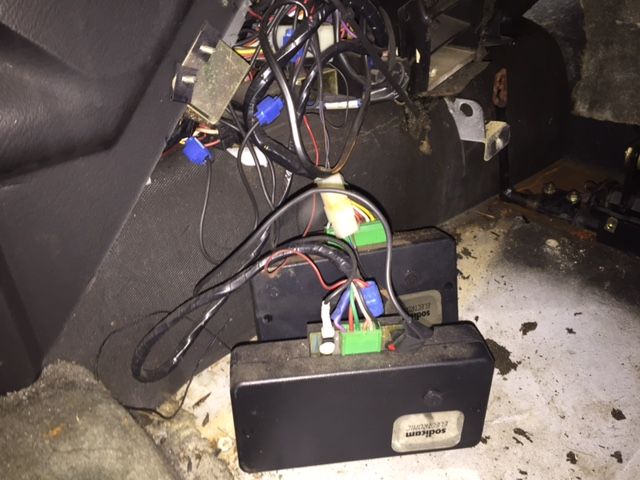

Major alarm system to be stripped out. Bodged with scotchlocks :0(

Should be all cleaned up ready for new shiny bits by the end of next week. Also going to have some strengthening of the rear subframe and mounting points done to cope with 475 ft/lbs.

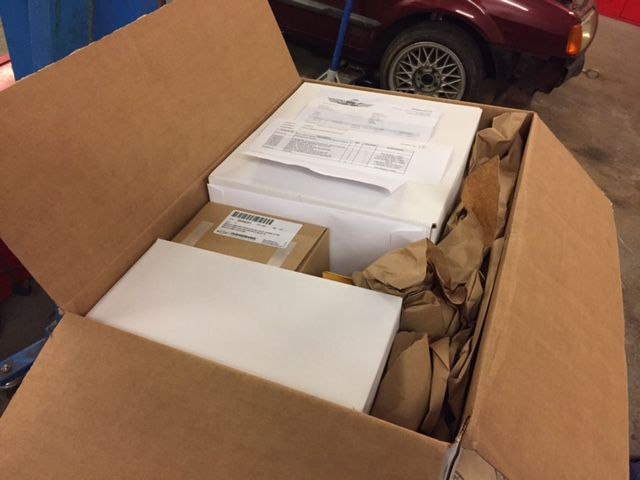

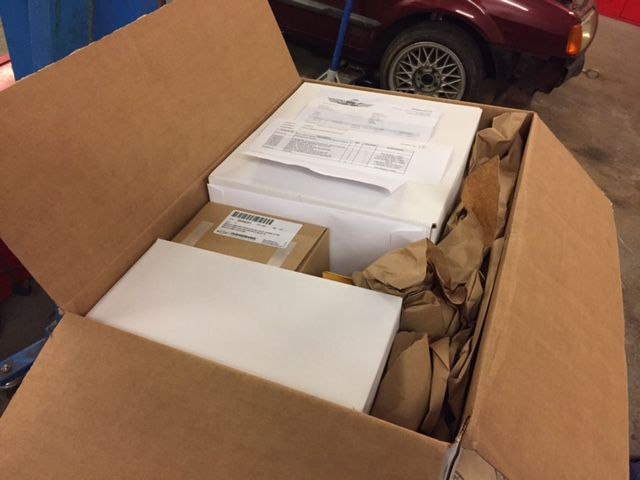

Power plant has arrived and is no bigger in anyway than the PRV :0).

Going round in circles with gearbox decisions this week, ending up with the more powerful lump means there is very little chance of the UN1 lasting long without serious modification. Had decided to go with the Audi transaxle box but then found out it has a fixed diff so cant be turned round to run rear engined like a UN1 can. You can't believe how many versions of the UN1 box there have been. They reckon the best ones are the A610 box or the Lotus V8 later the better. So have to decide whether to buy a second hand one of these , or rebuild one of my UN1s with a better diff and uprated main shaft coupling. These 2 options are still extremely marginal and will probably require me visiting church everytime I put my foot down. So that leaves me the expensive option of an off the shelf 6 speed 'box which will cost me more than the engine or rebuilding a UN1 with Quaife single piece shaft kit and LSD. You cannot believe how much these parts are. £2500 for the shaft and gears !!

Any of the clever people on here know anyway I could strengthen the spline coupling. Could it be welded? Also are new 2 piece splines still available from Renault as I'm told spline wear is a big contributor to the sleeve failing. Would it be possible to copy the 2 piece splines in a stronger material , possibly with a cut of spline that has more torque resistance?

Commissioned Chris Cole to build me a gearbox, he had the one piece shaft kit and quaife on the shelf, expensive but at least I'll be able to use the engine to its full potential. And a lot cheaper than some other people are asking . Hi Spec 4 pot calipers with 300mm discs all round also on their way and Spax Krypton suspension with 2 1/2 spring conversion too. Be some nice shiny bits to unwrap next week or two.

Project is now starting to take shape nicely. Rot busting now pretty much done, affected areas all coated with rust inhibitor and will be finished in a special protective paint usually used to protect fibreglass yachts.

Rear turrets all repaired and treated - good as new :0)

Some nice bits turned up this week too :0).

300mm discs and 4 pot calipers to go on all round, along with 5 stud hub conversion (thanks Haz for those :0))

ECU, loom DBW throttle pedal and sensors to run it

Next week should be final body prep and subframe strengthening.

Engine bay all refurbed ready for the 6.2 litre monster

Alpines - GTA 3.0 Turbo, GTA 3.0 Inj (Project DD), GTA 6.2 V8 (500 bhp) , R32 Skyline GTR, BMW Alpina B10 635 Highline, Alpina B10 E39 5 Series, Jaguar 4.2 XKR, Laguna 205GT, BMW 120d.